A slice of dried lemon floats in a cup of black tea.

With each sip of the tea, the fragrant scent of lemon slowly rises and a refreshing tartness fills your mouth.

Although lemon tea is quite common in the tea market, the Float Lemon Tea, which contains a full slice of dried lemon with the tea bag and in each package, is a product unlike any other.

The finest quality tea leaves and lemon have been selected so the flavor is sure to please.

The company that produces Float Lemon Tea is Mitsuura-jozo, a miso brewing company in Hofu City, Yamaguchi Prefecture.

One might wonder what a miso brewing company has to do with tea. Mitsuura-jozo is a long-established miso brewery that was founded in the Edo period (1603-1868) and it has been in business for over 150 years.

So why did such a company start making lemon tea?

We talked to Kentaro Mitsuura, the 8th president of Mitsuura-jozo, who has expanded the company’s business into new and international fields with his unique ideas.

A 150-year tradition loved by locals

First, let’s dive into Mitsuura-jozo’s unique history in making miso.

Mitsuura-jozo is located in a quiet corner along the Kouchi River, which is just a stone’s throw away from the ocean. The gentle ocean breeze is soothing and it is a place that makes one want to sit and gaze at the scenery for hours.

Mitsuura shares, “I spent most of my childhood here, where I would go fishing and play soccer in the yard. Sometimes my soccer ball would fall into the ocean and the fishermen would pick it up for me. There used to be so many horseshoe crabs that I would step on them when I walked around. Even now, I enjoy taking breaks in this garden.”

(President of Mitsuura-jozo, Kentaro Mitsuura.)

The air around the factory was filled with the aroma of freshly steamed soy beans. Miso is made by mashing softened soybeans, mixing in salt and koji (malted rice), and letting it age for several months.

There are several old wooden barrels lined up in the warehouse, and Mitsuura says it is because he wants to take good care of their old tools and continue to utilize them.

Most of the miso that is produced in Japan is a rice malt miso, but in Kyushu and Yamaguchi Prefecture, barley miso made with barley malt is also popular. Compared to rice miso, barley miso has a fuller sweetness, as well as a more mellow and gentle taste. It goes well with miso soup that is made with a lot of ingredients and Western style dishes.

(Mitsuura stands with the previous company president, Shintaro Mitsuura.)

In the past, Mitsuura-jozo used additives in their miso, but ever since Mitsuura became president, they gradually decreased the amount of additives and have now converted to using only natural ingredients.

They also use wheat and soybeans that are produced locally in Yamaguchi Prefecture. Even their koji is made from scratch. In order to fully bring out the natural sweetness of the koji, they heap it into thick piles in the koji fermenting boxes which are made larger than the standard size. This raises the temperature and activates natural enzymes.

Their ratio of koji to soybeans is 2.5 to 3 times that of ordinary miso.

“I want to keep this miso warehouse in operation for a long time. As long as our customers find our miso to be delicious, that is all that matters.”

Throughout its long history, Mitsuura-jozo has been producing miso that has been loved by the local people. They have worked diligently to be where they are today.

Miso maker meets lemon tea

So how did Mitsuura-jozo, which had been dedicated to miso making for so long, decide to produce lemon tea?

Mitsuurao says that after he graduated from Tokyo University of Agriculture, he did not hesitate to join the family business.

“At the time, I was quite the uninteresting person. I did not have anything I particularly wanted to do in my life. It just so happened that I was born into this family and I went to college with no worries in particular. After I graduated, the family business was there for me to join, so I returned home.”

However, once Mitsuura started working in miso production, various problems came to light.

Although Mitsuura was proud of the long history and tradition of his family’s miso brewery, in some ways it was a saturated business where nothing innovative would occur if they simply carried on as they always had.

In modern Japan, bread has become as much of a staple food as rice, and it was unlikely that miso would explode in popularity or sales in the future. The options were to quietly continue the business with no prospective of growth, or begin something completely new.

“Many miso factories make snacks using miso, but I wasn’t attracted to that idea. I was quick to completely discard those ideas from my mind. I believed that making only small changes would not lead to any good.”

When Mitsuura became president, the produce lineup at Mitsuura-jozo expanded beyond miso and soy sauce to include new products such as seasonings, sweet sake, lemon tea, straws and more.

Of these products, the Float Lemon Tea that was introduced at the beginning of this article, quickly became such a huge hit that production could not keep up with demand.

(To utilize domestically produced ingredients as much as possible, the lemons are sourced from Setoda, Hiroshima Prefecture, and the tea comes from Miyazaki, Shimane, Nara, Shizuoka and other regions of Japan.)

“I often get asked the question of why a miso maker decided to produce lemon tea (laughs). However, it is because we started a completely new genre that we were really able to expand the degree of freedom in what we do.”

The majority of Mitsuura-jozo’s customers in the past were large order clients such as hospitals and school cafeterias.

This meant that their business was relatively stable.

However, working with a limited number of large order clients alone did not hold any potential growth for the future. This worried Mitsuura, so he studied how to create a website and started an online store to reach a larger population of customers.

While doing so, he realized that his family business had not put any consideration into small lot and retail sales before.

The products they sold were limited to 20 kilogram packages of miso, and large 1.8 liter bottles of soy sauce. None of their products were sold in a size or volume for general consumption of regular customers.

So the first thing he did was create family-size packages of miso, but the heavy weight of miso meant high shipping costs.

As Mitsuura was thinking about how he could create a lightweight, yet high-value product, he had the chance to visit a friend’s company which produces commercial food drying machines. Among the various dried fruits he saw at the company, he took notice of a dried slice of orange.

“Although dried slices of fruit are not uncommon now, they did not exist in the Japanese market 14 or 15 years ago. I was very surprised to learn that such a product could be made.”

It was at this time that the idea to combine black tea with dried lemon slices struck his mind.

Tea is very lightweight, and the product would make a pleasant gift. At the time, there was no other product quite like it.

He moved quickly to install a food dryer in his factory and began brushing up on his idea to make it into a commercial product.

“Drying sliced citrus fruit is actually quite difficult. Freeze-drying them causes them to crumble, and simply drying them makes their color turn black. It required a special technique to dry them evenly while maintaining their beautiful color and shape.”

(Candy Lemon is a new product that they are currently developing.)

“I enjoy searching for answers through trial and error to problems that are not straight forward and cannot be easily resolved with a Google search.”

Mitsuura also creates his own package designs. He was inspired by the design on the old soy sauce labels that were stored in his warehouse to create his current product labels. Although he had no previous interest or training in design, he taught himself how to use Illustrator to create his original design.

Even though it is a simple lemon tea, it signifies the culmination of all the work that went into creating something new for his family business. From finding new drying techniques to creating the package designs, this new product was an epitome of his persistence and dedication.

(During a tour of the company’s factory for making dried lemon slices, we saw how each sachet is carefully inspected and boxed.)

Mitsuura does not boast about his originality or hard work that he put into making these new products. This attitude seems to reflect his background as a miso craftsman whose sincere work ethic isn’t anything out of the ordinary.

As retailers and general merchandise stores asked to handle their Float Lemon Tea products, their sales channels gradually expanded. Although it is now one of Mitsuura-jozo’s signature products, Kentaro never imagined it would sell so well.

One-of-a-kind product made by a miso maker: straws

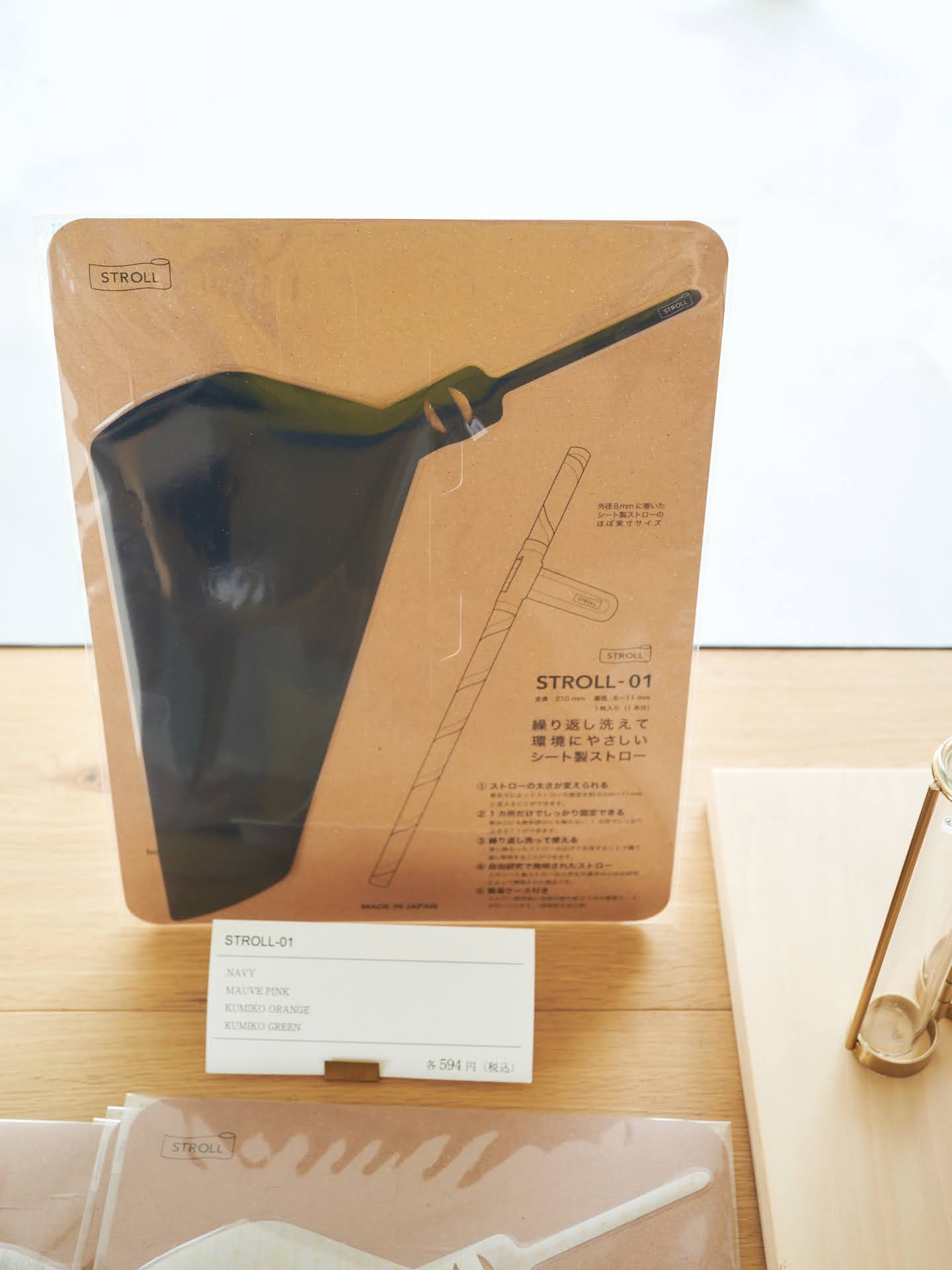

The next product Mitsuura developed after lemon tea was once again very unique. He developed a new type of straw.

The product name is STROLL, and it is made with a thin sheet of plastic that can be turned into a straw by rolling it lengthwise.

It is lightweight and easy to wash so it can be used repeatedly, making it an environmentally friendly product. Because the product has a flat sheet shape, various designs and illustrations can be printed on its surface so it can be made into an appealing gift or corporate novelty.

In fact, it was Mitsuura’s 8-year-old daughter who came up with the idea behind this product.

She presented the idea as a part of her free research project over summer vacation. Her science teacher was so impressed that he told her that she could probably get the idea patented.

When his daughter shared this feedback to him, he began spending all his spare time developing a product based on her idea. He also researched and studied how to get a patent, and after a year and a half of intense work, he successfully obtained one.

“When I was studying the topic of intellectual property rights, I found that there were so many things that I did not know and it was really eye-opening. For example, I had to learn how to obtain a patent, how to explain the process of manufacturing something, and how to describe a product that had not existed in the world before. I really learned a lot in the process and although it was not easy, it was a great experience for me.”

Again, Mitsuura produced a product that has nothing to do with miso, however his underlying desire in all his products is to “enrich the Japanese food experience.”

With this desire at his base, he has been able to keep a free and open mind to create new products and experiences around food.

Mitsuura-jozo’s corporate philosophy states, “Bringing together flavor, people, and…” With their long history in miso making as their foundation, they aim to present the richness of food with simple combinations of ingredients and provide new joyous experiences.

The final “, and…” in their statement is there to express their intention of continuing to develop products in an organic and undefined manner, leaving it up to nature and the users to define their course.

Although they are a well-established and historic miso brewery, miso is simply one of their means to an end.

If a miso maker were to get into bread making…

In 2022, Mitsuura-jozo came up with another new idea and they opened a bakery called ebb & flow on their factory premises.

For a long time, bread has been considered a rival food to miso and Japanese cuisine because, as eating bread for breakfast became more mainstream, the consumption of miso soup declined.

The people of the miso making industry have been contemplating how to stem this trend for years.

Mitsuura says, “In fact, miso and bread are both foods that are made through fermentation, so they are part of the same food group. We make barley miso, so we even use the same ingredients. I wanted to create a movement in which miso makers also become bread makers, and when consumers go to a miso shop, they can also buy bread.”

(ebb & flow opened in 2022. The shop is filled with the joyous aroma of delicious bread. The table used to display the bread was made from refurbished wood of old miso barrels.)

Miso soup is now very popular worldwide, especially in Western countries among health-conscious people. It is no longer strange to pair miso soup with bread.

Mitsuura-jozo makes their bread with four types of homemade natural yeast, including one made from their koji (rice malt). Their goal is to make a bread that is uniquely Japanese.

To make the bread, they incorporate a traditional fermentation technique called Bodaimoto that was developed in the Muromachi Period (1336-1573). The traditional method is a slow fermentation method that incorporates natural lactic acid bacteria and yeast that live in the air.

Their experience and knowledge for miso-making is being incorporated in their bread making.

Mitsuura says, “I wanted to make a bread that is unlike any other.”

Using mostly locally grown wheat from Yamaguchi Prefecture, they keep their ingredients very simple and do not use eggs, milk or butter. Kneading in amazake (sweet sake) creates a fluffy, chunky texture and also adds a natural sweetness with a deep, rich flavor.

It is a bread with a gentle flavor that can be eaten everyday, much like rice. Because it leaves the fermentation process up to nature, it is a living bread that is the same yet different each day.

“The fermentation changes slightly depending on the weather each day, so it is not always the same. However, I hope people can enjoy the different flavors that come from these inconsistencies.”

“I want to create a culture where it is commonplace for miso breweries to make and sell bread. We hope to establish a business model for that here so that we can share our knowledge to anyone who wants to learn how to make bread like this.”

The Bodaimoto fermentation technique is time consuming and labor intensive because it is difficult to control the temperature and humidity that is necessary for it.

Tokumoto, the manager of the bread shop says, “Bread is like children. Some days you find that they are happy and some days they are grumpy. They take up a lot of time and effort, but we put in a lot of love and trial and error to nurture them.”

Their bread shop has become a big success, with many customers coming everyday. Even on the day we visited there was an endless flow of customers.

(Bread shop manager Rumiko Tokumoto used to be a nutritionist but had a love for bread making and often sold bread at events.)

Fermentation and brewing: a perspective unique advantageous to miso makers

As Kentaro continued to develop new products, his vision for Mitsuura-jozo’s future became clearer.

Although he claims, “It is becoming continuously more difficult to develop innovative and new products”, he is still coming up with new ideas. One of his new ideas returns to his roots in miso making.

He is currently working on creating a kit that allows consumers to make their own miso using the ingredients of their choice.

“I have been tending to this idea in my mind for years now, and I think it will be a groundbreaking product once it is ready. Miso can be made with an endless variety of ingredients and methods. There are regional and cultural characteristics of miso, so miso breweries usually do not make a variety of products. However, I would like people to learn about the diversity and endless possibilities of miso and enjoy the process of making it themselves.”

At Mitsuura-jozo, products are developed with long tail strategies in mind. Kentaro says that “Products that are easy to sell easily become hard to sell.”

While many start-up companies focus on speed, Mitsuura-jozo’s approach to product development deliberately focuses on the long term. This mindset has been nurtured by the company’s long history of working with the slow fermentation and aging processes of making miso.

“I am very aware of the fact that crafting something takes time. It takes months for miso to age before it is ready to sell.”

“When I was developing a new miso made out of chickpeas, we worked with prototypes and had to wait for them to mature. When they were finally ready and we found that it did not come out well, the process started all over again. It took us five years of trial and error until we were satisfied with the result.”

Mitsuura says that the time spent waiting for fermentation and aging is very meaningful in creating and nurturing new products. He has a solid trust in the process of taking time, which seems to come from wisdom accumulated through the company’s 150 year history.

(Miso De Garbanzo (chickpea miso) took 5 years to develop. )

Different perspectives, new ideas

Mitsuura respects tradition while also exploring the creation of unique and new products. We asked him where he finds inspiration for his ideas.

He says, “I go back and rethink things that I am not supposed to do.”

“Most people don’t do what they think they shouldn’t, or things that they don’t need to do. Because we don’t know what will happen if we do it, we subconsciously stop thinking about it.”

“One tea maker told me that they thought it was taboo to put lemon and tea in the same packaging. People thought that taking apart a straw and rolling it up again is pointless, so normally they won’t do it.”

“In our world today, we can easily look something up online to find answers to our questions. If we look up how to make bread we can find a recipe right away, but that does not lead to anything new, does it?”

“Making yeast with the Bodaimoto method or bread with sweet sake is not something people usually do. However, I find that exploring unknown territories by taking action and finding answers on your own leads to many new discoveries.”

(Cap)The office is located next to their shop and the space was spacious with a lot of natural light.

Mitsuura thinks about the origins of how products were made in past generations and when he approaches a crossroads he decides which path he will follow by trying something new.

He says this becomes the catalyst for innovation.

If you only had the option of going left at a crossroads in the past, you may find that with the new technologies available today, or with your new knowledge and experiences, it is now possible to go right. By taking time to think at a crossroads, you may discover something unexpected.

“One example is, in the past when there was no electricity people may have had no choice but to do things a certain way, but in this day and age there are probably other options. I think about how I would approach making soft and fluffy bread in the Muromachi period (1333-1573) when there were no eggs or butter available.”

On a different note, Mitsuura’s father and previous president of the company did not oppose any of his innovative and perhaps unorthodox projects.

His father was very supportive and told him, “I think it is good to take on new challenges and do what you can. I envy you.”

Yamaguchi Prefecture is known as being the birthplace of many famous historical figures including Shoin Yoshida, Shinsaku Takasugi, and Hirobumi Ito. It is also where world-renowned companies such as UNIQLO and Ashahi Shuzo started.

Although this gives the impression that the region must be glamorous and rich, Mitsuura is worried about the decreasing population and the region’s conservative mindset. He says that under the current circumstances, the future of the miso industry is not bright either.

“If I can contribute to revitalizing the community and shine a new light on the region, it would make me very happy.”

With time on his side, Mitsuura’s challenges into the future will continue.

Photo:Umihiko Eto

Translation: Sophia Swanson

Advisor to corporations, and local governments on promoting local tourism. Published work includes, “Aomori & Hakodate Travel Book” (Daimond), “San’in Travel: Craft and Food Tour” (Mynavi), “A Drunkard’s Travel Guide: Sake, Snacks, and Tableware Tour” (Mynavi). Her life work is to explore towns in her travels, drink at different shops and visit the workshops of different crafts. Interests include tea, the Jomon period, architecture, and fermented foods.

Editor. Born and raised in Kagoshima, the birthplace of Japanese tea. Worked for Impress, Inc. and Huffington Post Japan and has been involved in the launch and management of media after becoming independent. Does editing, writing, and content planning/production.