Food loss comes in various forms, from tea leaves after tea has been brewed, or the peels and cores of an onion after it is peeled. This is true in our individual everyday lives, so it is not hard to imagine the massive amount of food residuals that are inevitably produced in food factories.

We have to question, is continuing this kind of massive food loss really acceptable for the future?

There is a venture company that is making great strides in addressing this very issue.

ASTRA FOOD PLAN is a food technology venture that develops and sells food dehydrating equipment that utilizes superheated steam technology.

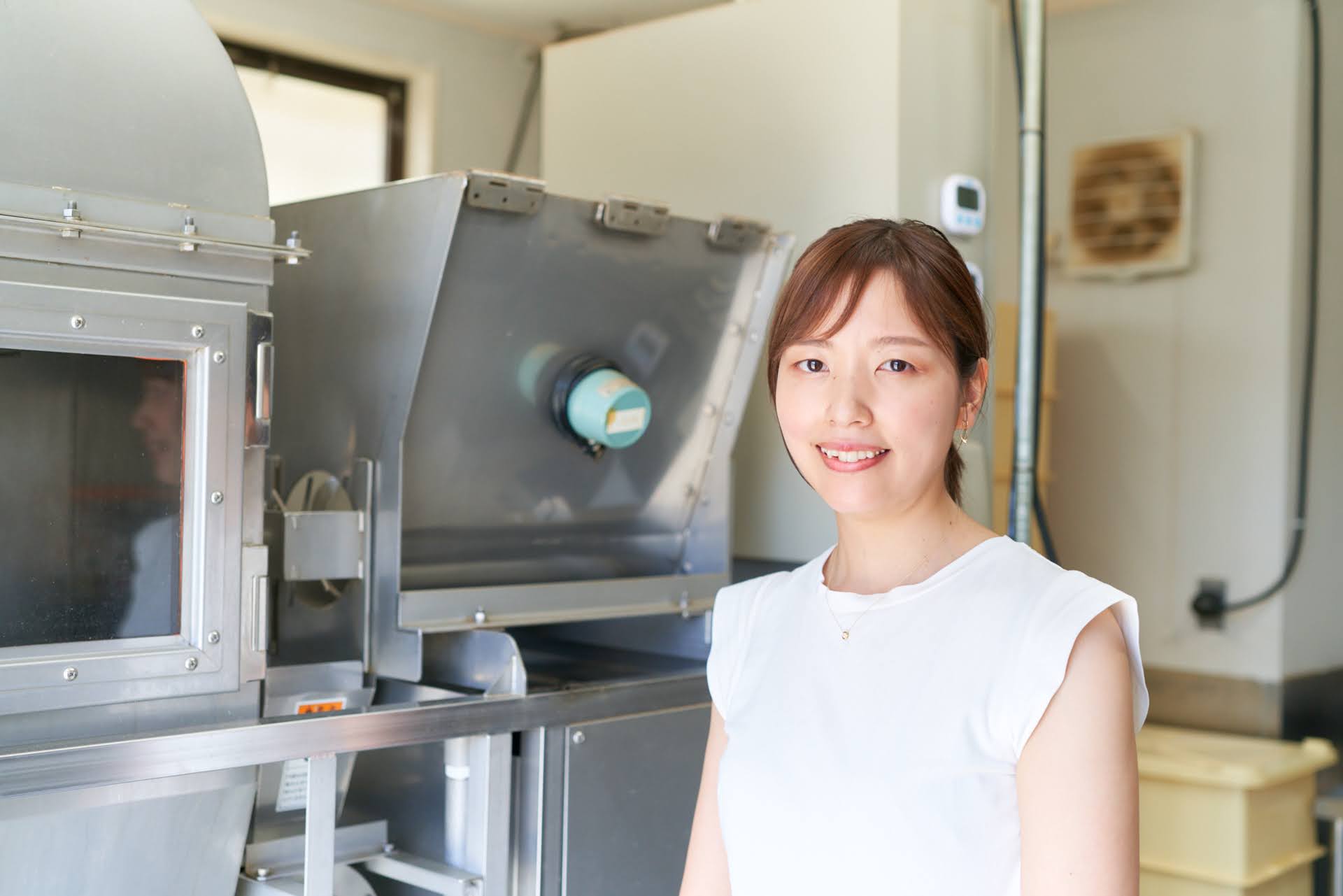

President Chihiro Kano stands in front of their equipment and explains, “We are not processing waste, we are creating new food products from food residuals.”

ASTRA FOOD PLAN aims to make the most of food resources and create new food experiences. At DIG THE TEA, we pick up on initiatives and innovators who are focused on realizing a more sustainable world.

For this article, we visited ASTRA FOOD PLAN’s laboratory in Fujimi City, Saitama Prefecture, to talk with Kano about the buzz she has created over the issue of food loss and the technology behind her patent-pending equipment that will create new value for food residuals.

The advantages of steaming

“Many big food and beverage manufacturers in Japan have already visited our lab. I was surprised to learn that all of them were very conscientious about the issue of food loss. It made me realize that there is no food related company in the world that is not faced with the problem of dealing with hidden food loss.”

The superheated steam technology developed by ASTRA FOOD PLAN uses their original equipment to dry and sterilize foods using 300〜500℃ high temperature steam.

“It can dry all kinds of food scraps, from vegetables such as onions, carrots, and cabbage to mushrooms, fruit and even natto (fermented soybeans).”

“An olive orchard in Kagawa Prefecture found our work to be very unique and asked us to test roasting olive leaves to make tea. They had tried drying the leaves using conventional drying equipment, but it produced a bitter tasting tea and was unsuccessful. We found that using our superheated steam technology created a delicious olive tea that did not have any bitterness.”

The superheated steam technology only heats the produce for 5 to 10 seconds and combines hot air to achieve high speed drying and sterilization. Once the ingredients are dried, they come out as flakes.

“The reason why the produce does not get burnt in such high temperatures is because they are heated in a fine mist. At first, we used the term roasting to describe the process, but many people associate that word with the process of burning coffee beans. We needed to come up with a new term to properly describe the process without giving the idea that the product is burnt or oxidized. Our executive director Yoshikoka, who developed the equipment, came up with the term superheated steaming.

The speed at which the materials dries helps to prevent the food from oxidizing. It also helps to retain the nutritional value and flavor. In fact, the nutritional value and flavor of some ingredients are actually enhanced in this process.

Although the technology sounds similar to that of freeze drying, in which wet produce is frozen and then dried, freeze drying requires a full day in order for the produce to dry completely.

By contrast, the boilerless superheated steaming uses hot air to achieve an extremely energy efficient drying and sterilization that can process large amounts of produce in a short period of time, making it much more cost efficient and less time consuming than freeze drying technology.

“Even our smallest model can powderize 50 kg of produce in one hour. Depending on the produce it can powderize about 300 kg in one day. We have developed models in five sizes and our largest model can dry and sterilize 3.5 tons of produce in a seven hour work day.”

A company that jumped to the potential of this new technology was the major restaurant chain, Yoshinoya Holdings.

Yoshinoya is famous for their beef bowls and because onions are a key ingredient in their signature dish, they produce a large quantity of onion scraps such as cores and peels every day. Using the superheated steaming machine they utilized onion scraps to make onion flakes, which is kneaded into onion bread developed and sold by the bakery chain Pompadour. This collaborative initiative between two companies garnered a lot of attention.

Now, various companies visit the lab to test how they can upcycle their residual foods.

Where the paths of father and daughter merged

Kano looks back on the founding years of the company in 2020 and says, “Initially, our only goal was to make good quality equipment and sell it.”

Ever since childhood, Kano has been very interested in food.

“My father worked in product development for Seven-Eleven so he would often bring home his prototypes and let my mother and I taste them. I still remember how interesting it was to hear my father talk about how he worked with daikon radish farmers directly to create the oden (stew) menu.”

“My mother was a certified nutritionist and before I was born she worked as a secretary at the same office as my father. Naturally, food was a very common topic of conversation in my household.”

Kano knew that she wanted to pursue a food-oriented career, so after graduating from Kagawa Nutrition University she started working at a company in the food industry. She was in her early twenties when her career crossed paths with her father.

“I was planning on getting married, but that fell through. I had already left my job so I felt very distraught at the time, but my father had also left his job at Seven-Eleven and had started a company to produce fruit puree using superheated steam ovens. I was given a job there and we ended up working together.”

Their relationship of father and daughter became one of president and employee. Kano was in charge of corporate sales and she witnessed her father’s passion and struggles of being a business owner first hand. Eventually, this experience led to her founding her own company, ASTRA FOOD PLAN.

“Although my father is much more mellow today, back then he was very stubborn and a hard headed developer. As I watched him run his business, I thought about how I would do things differently.”

After many trials and tribulations, Kano eventually left her father’s company. She worked on launching a new brand at Eitaro Sohonpo where she worked on product planning and she also worked on developing delivery lunch boxes for another company.

In 2017, the father and daughter’s career paths crossed again.

Kano remembered how her father had made carrot puree in a superheated steam oven when she was a child. The memory of being enthralled by the delicious puree made her want to work with her father once again.

At first, she joined her father’s newly established research and development company for commercial superheated steam ovens as a corporate sales representative. However, their business came to a sudden halt during the coronavirus pandemic. Kano witnessed her father being forced into retirement. She wanted to encourage him to fight for his dream again so she started a new company based on some newer technology with her boss and current senior managing director, Yoshioka.

Although Kano intended on having her father act as the company president, right before the company was founded her father approached her and asked her to serve as president.

Kano accepted the offer right away and knew that she was ready for the role.

It was at that moment that all her experience in food production, sales, product development, branding and corporate sales came together to bring ASTRA FOOD PLAN to life.

The need for both an entrance and exit

Although the company’s business scheme for the first year was like working in the dark, they gradually found their direction.

“At first we planned on developing the business by selling equipment, but this was not enough to make a viable business. We decided that we could use the steaming technology to process foods and make a business out of the powdered end product.”

“The superheated steam oven to make puree that my father first made produced a really delicious end product, however, there were many limitations in usability of the products in puree form. We decided to dry the products and create powder instead. We developed equipment that can dry any kind of produce and also made suggestions to our customers on how to use the powder and commercialize the end product.”

“In other words, we realized that our customers needed both an entrance and exit for their products.”

Kano closely studied the trends in the market to come up with ways to promote their products and really make an impression.

“Rather than marketing the equipment as a machine that can dry any food product, I found that it was better to market it as a technology that can help achieve SDGs and resolve food loss issues. This really resonated with a lot of companies and it clearly caught their attention.”

In today’s world, there is a lot of emphasis on what kind of positive contributions a company makes on the global environment when looking at the overall supply chain.

Food loss, which comes from leftovers or expired food items is one problem, but another less known problem is the food scraps that are produced in factories which can add up to over 2,000 tons per year.

“Before, the only options available were to spend money to dispose of the waste or compost it. Turning the food into powder allows us to transform it into a new product, sell it and create new sales. I believe many people find this aspect to be very appealing.”

Many of the food scraps and residues are edible, but because it is not common knowledge that such a large amount of food goes to waste everyday, Kano began calling it the “hidden food loss.” ASTRA FOOD PLAN’s originality lies in the fact that they found a way to bring new value in waste and transform it into new food ingredients.

Simply declaring that something is “wasteful” is not enough to urge companies and people to take action. Creating delicious ingredients that bring new value to products is what leads to a more sustainable future.

The beginning of social implementation

We asked how the name ASTRA FOOD PLAN came to be.

“ASTRA is the word for star or celestial body in Latin. We chose the name ASTRA FOOD to express our desire to create something that goes beyond superfoods, or products that are both good for your body and eliminates food loss. We added the word PLAN because we want to be a company that not only manufactures products but puts new systems into place.”

ASTRA FOOD PLAN calls food residue “hidden food loss”. They describe their technology as “superheated steaming” rather than roasting, and they aim to go beyond the creation of superfoods by creating what they call “astra foods”.

New terms bring life to new ideas. We were impressed by their incredible knack for business as they create one new term after another to describe the new values in our current world.

Lastly, we asked what developments they have in store for the future and Kano had a lot to share.

“First we want to establish a model that works closely with JA Group (Japan Agricultural Cooperatives) to solve the problems of hidden food loss among food producers. We want to work with the local school lunch programs in Saitama to help develop new recipes and work with local bakeries to develop new products. We plan on working with industrial, governmental and academic fields and start many experimental projects as we move onto social implementation.”

“We are also looking into finding a way to utilize the massive amounts of food residues that come from beverage producers such as tea and coffee factories. Can we make paper plates by mixing these powders into paper pulp? Residue from making beer is low in sugar so perhaps it can be used to make a new kind of flour besides wheat flour. Tea leaves and coffee grounds have deodorant properties so they can be mixed into deodorants or plastic that is used to make garbage bags. We believe in open innovation and plan on experimenting with a lot of possibilities.”

While their company vision aims for new heights, they remain grounded as the company’s growth accelerates.

We look forward to seeing how ASTRA FOOD PLAN’s various projects take off as they bring their products into the market and see where they will be in five to ten years’ time.

Photo:Umihiko Eto

Translation: Sophia Swanson

Editor. Born and raised in Kagoshima, the birthplace of Japanese tea. Worked for Impress, Inc. and Huffington Post Japan and has been involved in the launch and management of media after becoming independent. Does editing, writing, and content planning/production.